VI Miners' Changing Wage LevelsUnderground miners are the key workers in any mine operation, and they also happened to be the principal participants in the Ashio riot. This chapter will examine changes in their wage levels over the period 1883 to 1906. For ease of reference, Table 33 reproduces data relating to miners' wages culled from tables 16 and 17.

[Notes] The wage amounts are in sen(¥1/100).

1) The Causes of the 1884 Wage FallChanges in the method of determining wages

Miners certainly suffered a marked drop in wages in 1884. Both sets of data for 1883 and 1884 stem from the mine reports for those years issued by the company office at Ashio and are therefore easily comparable. Why then was there such a substantial drop in nominal wage levels? Two factors which may go a long way to explaining the 1884 wage drop are a general fall in prices caused by the Matsukata deflation policy on top of the effect of a collapse in the price of copper. The price of consumer goods was 5% down on the level of the previous year, and nominal wages had shown a tendency to fall accordingly. At the same time, there was a sharp decline in the price of copper. Copper being an international commodity, Japanese copper prices were in effect decided on the London market (see table 34).

[Notes]

1) a = Jan.- Jun., b = Jun. - Dec. 2) 100 kin = 0.6kg; 3) s. = shillings, d = pence 4) London market data: "100 Years of the Furukawa Company" Furukawa Company centennial publication p. 88 5) Besshi finished copper data: "Bulletin of the Japanese Mining Industry Association" No. 1 (March 1895) p.72-73 6) Ashio rough copper data: "History of Tochigi Prefecture" Historical Documents - Modern 9, p. 148. One could well imagine that the falling copper price would have put pressure on the company to cut costs and thus lower wages. Also, in the same year, owing to the fact that the refinery workers were unable to keep pace with the increased output from the pits, considerable quantities of unrefined ore accumulated at the mine, which may also have served to reduce miners' wages. However, these factors alone fail to account for the problem, since despite the continuous fall in the price of Ashio copper through 1885 and 1886 and the overall drop in consumer prices, the drop in nominal wages was by no means significant, while real wages actually showed a substantial increase. The answer to the problem is more likely to be found in 1883. May it not be that wages fell in 1884 because they had been inordinately high in 1883? After all, 1883 was the only year in which nominal wages shot up, while in the years after 1884 they tended to rise by modest increments. The change in the method of determining miners' wages in 1884 may also have affected the situation. Kimura Chôshichi, Ichibei's right hand man and the executive in charge of Furukawa Company management at the time, later wrote: 1) "Previously, the company had purchased copper ore (from the contractors) by buying at a certain rate every 100 kan (= 375kg) refined per miner; each miner's ore was stored separately in half-monthly amounts. But as work progressed, and the stores filled up, it became difficult to deal with the excess. This method could not cope with very large amounts of ore, and it was felt necessary to change it. I had been discussing the matter with Mr. Chôbei and it was decided that, since the present method could not possibly be used at the Ônaori lode, a more appropriate method of assessment should be instituted. Raw ore would now be assessed instead, and received direct from the ore extractors at the end of each day's work." There are doubts as to the accuracy of some of the details of Kimura's account here. He does not clarify the nature of the change in the ore purchasing procedure. However, the discovery of the Yokomabu bonanza lode in November 1882 and the completion of the ventilation shafts in February 1884 meant that the need to revise wages was pressing. Prior to the change, although 'finished copper purchasing' was the stated pro forma method, 'raw copper purchasing' was the reality. In other words, the ore dug by each individual miner was refined on an individual basis, and each miner was paid according to the amount (weight) of rough copper which resulted. If that were not the case, there would have been no need to have kept two weeks' worth of individually dug copper in storage. It was individually marked and stored until enough was accumulated to be sent to the smelting furnaces where 200 to 300 kan (750 - 1,125kg) was the minimum limit for a single firing. Wages were thus determined after smelting. In any case, the discovery of new rich lodes meant that the individual miner's output would increase, in which case, failure to switch to a proper piece rate system for determining wages would mean that miners' wages levels would rise inexorably. Nevertheless, it was not possible to change wage assessment as soon as as new lodes were discovered; that would only provoke resentment and anger among the miners. On the other hand, to do nothing would mean a decline in miners' efficiency and will to work. Management were of course always urging their workers to work harder, but in 1883 their urgings were particularly necessary. Despite the discovery of the Yokomabu Ônaori bonanza lode the previous November, ventilation was still a severe problem. Lanterns would not burn at the ore faces, and breathing difficulties made it impossible for a miner to work for more than one hour at a time 2). In such circumstances, it was imperative to speed up the work on the ventilation shafts and to increase output in order to have the capital necessary for opening up new pits. It was certainly a period when maximum motivation was required from the workforce, and the decisive factor in stimulating that motivation was the payment of unusually high wages. That this was conscious management policy is confirmed by the Pits Department Budget Report for the second half of 1883 which provided for men working on opening up new pits to be paid the considerable wage of an average 38 yen 23 sen a month. This situation was drastically affected by the completion of the ventilation shafts in February 1884 which led to an improvement in the working environment and an increased individual output per shift of almost 50% over the previous year. Under such circumstances, wages could only go up, and management was understandably faced with the need for a revision of wage determining procedures. But this time, it was not enough simply to cut the rate at which the company bought up the copper in the rock extracted by the miners; instead, a thoroughgoing revision of the whole method of wage determination was urgently called for, and indeed had become inevitable, because to continue the method of 'rough copper purchasing' would be to hold up the modernization and mechanization of the ore dressing and refining processes. To dress, smelt and refine each miner's ore on an individual basis was simply incompatible with mechanization. It was clearly necessary to purchase raw ore and then dress, smelt, and refine it altogether. This was how Kimura Chôshichi saw the problem. It was from this period that the wage determination system was changed to one in which the raw ore dug by each miner was assessed for quality and weight by a company official. The change was a double blow for the miners in that, firstly, it led to a de facto cut in wage unit costs, and secondly, whereas under the old 'rough copper' purchase system, each man's output could be determined fairly accurately, the new raw ore purchase system meant that as long as the assessment of the raw ore did not include any chemical analysis, it was bound to be arbitrary, and indeed, this very arbitrariness was later to become one of the main sources of bribery-related friction between miners and officials. 2) The Fall In Real Wages in the 1890sThe effects of the Pollution Prevention Order

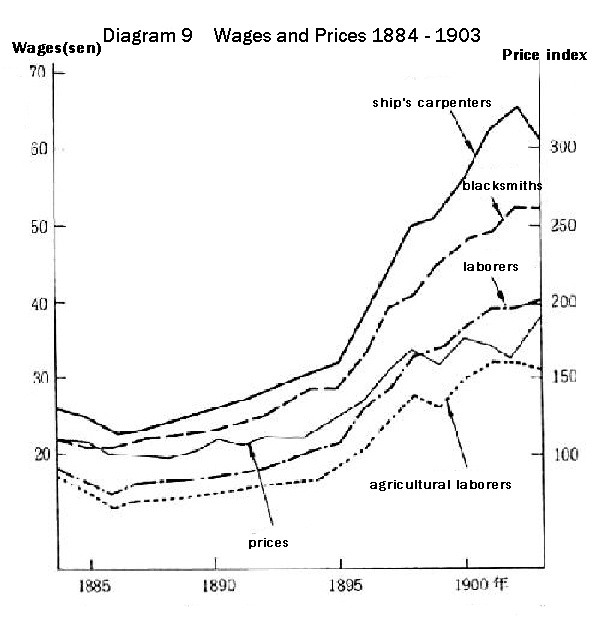

What were the reasons for the decline in real wages between 1897 and 1901? Yet this same period, from the late 1890s to the early 1900s is normally regarded as one in which real wages levels rose. Prices may have risen after 1895, but the increases were more than matched by rises in nominal wage levels throughout industry (see diag. 9). Why did Ashio buck this national trend?

[Notes]

1) Cabinet Statistics Office "Statistical Chronology of Imperial Japan", Ministry of Agriculture and Commerce "Wage Tables", and Ôkawa Kazushi and others "Prices" ("Long-Term Economic Statistics" 8).The data for price movements are based on the urban consumer price index, not including rents. 2) Hyôdô Tsutomu "The Development of Labor Relations in Japan" p. 204.

The reason has to do with the issuing of the 3rd Pollution Prevention Order on the 27th May 1897 by Minami Teizô, Head of the Tôkyô Mine Supervision Bureau. This third Order was more specific in its stipulations than the two which preceded it, which were issued on the 13th May, and in December of the previous year. It called for the provision of a waste reservoir, filter beds, desulphurization chimneys, and slag heaps and set time limits for such stipulations to be met - within 120 days for the lengthier jobs and 30 days for the shorter ones. Furthermore, the Order's final clause 37 stated that "if the provisions of this Order are infringed in any way, operations at the mine are to be suspended forthwith" 3). "The labor force for the construction projects consisted of bricklayers, stonemasons, carpenters, machinists, blacksmiths, miners, scaffolding erectors, navvies, and other laborers. On busy days, six or seven thousand men were at work on the projects, and at other times, two to three thousand men. The task of employing all this labor fell to the labor contractors: Kajima-gumi, Jôshû-gumi, Suzuki-gumi, Konishi-gumi, Iizuka-gumi, Tamura-gumi, Ichigaya-gumi, and Nakamatsu-gumi. Together with those workers who were already employed by the company and could be spared to take part in the projects, the labor procured by the contractors was finally sufficient to carry out the work. The total labor force engaged was 583,589 workers, who were paid a total of 4,173,874 yen 26 sen 8 rin, an average of 81 sen 2 rin per man a day. According to a recent survey carried out by Finance Minister Inoue, data relating to workers engaged in government-run industrial enterprises over the last three years reveal that such workers are paid an average of 54 sen a day. The wages paid by the company to workers engaged on the (Ashio) construction projects therefore exceeded the national norm by about 50%. Realizing that the work was urgent and had to be completed by a certain deadline, the workers and labor contractors pressed for maximum wage rates. Under the pressure of time, the company was unable to engage in detailed negotiations as to wage rates and had to concentrate rather on securing the necessary labor. Despite the company putting all its best efforts and ideas into the procurement of labor and despite similar efforts made by cooperative contractors, in the first 20 days only one tenth of the necessary labor was engaged in the work. It seemed unlikely that the work would be completed in the allotted time, and everyone was under the most severe pressure. In the last three years, many new enterprises have been started by both government and the private sector, and the total number of workers employed by both has risen to almost 90,000,000 a year. In such a situation where skilled workers were hard to find, it was bound to be extremely difficult to accumulate for just three months the 600,000 workers needed for the construction projects". While it is necessary to point out that the "Outline of Anti-Pollution Measures Taken at Ashio Copper Mine" was a company-produced public relations document, it is clear that the need to employ a large number of workers in order to complete the construction projects required by the Pollution Prevention Order within the stipulated time would certainly have the effect of raising wages rapidly. However, the average of "81 sen 2 rin per man a day" mentioned was in fact the amount determined by the company for labor costs and not the actual average amount paid to each worker. As the document mentions, between the company and the workers were a large number of intermediaries, the labor subcontractors (hanbagashira) who recuited men from all over the country. Their recruitment costs and their own "take" would also have been included in the figures given. Nevertheless, it remains true that the relatively high wages of the men employed on the anti-pollution construction jobs had a knock-on effect on the wages of Ashio miners, causing them to rise also. On the other hand, the sudden influx of a large number of workers to work on the anti-pollution projects also had the effect of forcing up local commodity prices and thus of depressing real wage levels. Increases in the price of daily essentials such as rice, miso, shôyu, and sake were particularly steep. The "Outline of Anti-Pollution Measures Taken at Ashio Copper Mine" records that "as most daily necessities are bought from local suppliers and markets, local prices of such commodities have risen sharply, mostly by an average of over 50% in just two months. Although work on the projects has now been completed, these price rises, being considerably higher than those in the rest of society, continue to have their effect and represent a substantial economic burden for the mine" 5). Table 33, based on a national consumer price index, showed a rise in nominal wages in 1897 that just managed to cover rising prices, and that consequently, compared to 1895, real wages of miners at Ashio had hardly fallen. Yet the rise in local prices at Ashio far outstripped price rises nationwide and thus could not fail to have a depressant effect on real wages. Management policy changesThe Pollution Prevention Order had an immediate direct effect on Ashio wage levels, but it had an even greater indirect effect in the long run. This was because the Furukawa Company, in its efforts to provide the necessary capital to cope with the cost of dealing with the worsening pollution problem, carried out a radical overhaul of its management policies. Since this impacted not only on wage levels but also on the entire structure of labor-management relations, we shall consider it in some detail even though it will lead us somewhat from our main theme. Since its founding, the Furukawa Company had been under the sole almost dictatorial control of Furukawa Ichibei. Company policy had been, to use Ichibei's own slogans, 'mining first' and 'growth at all costs' 6). This led to a policy of buying up as many mines, especially copper mines, as capital resources would permit and ploughing the maximum investment into the most promising of them to improve facilities and boost production. Prior to 1896, Furukawa had acquired 18 copper mines, 10 silver mines, 4 gold mines, 5 coal mines, and 6 others - a total of 43 mines altogether 7). It is usually supposed that Ichibei bought up so many mines as a result of the great success he had with the two copper mines, Kusakura and Ashio, he had bought soon after becoming his own boss. As a result of the rich lodes discovered at the two mines, which had been virtually closed, in 1884 they surpassed Besshi to become the two most productive copper mines in the country, accounting in the following year for 49% of the total national output. The success of the two mines convinced Ichibei that by using explosives and dynamite to sink ever deeper pits and shafts, the consequent discovery of more rich lodes, and the continuous introduction of new technology to improve ventilation, drainage, and haulage would considerably reduce production costs. Ichibei's two slogans were based on his firm conviction that the introduction of western technology would revive Japanese mining. Obviously, the failures of later years amply demonstrated that new technology alone was insufficient to ensure the success of all his mines, but Ichibei nevertheless continued to believe in his 'good fortune' 8), especially since the huge profits from Ashio's copper provided him with the capital to buy up more and more mines. Ichibei's aggressive style did not only show itself in his purchases of mines. He constantly sought to increase copper production by ploughing more investment into all aspects of mine operations - surveying, extraction, hauliage, dressing and refining - at the major mines, especially Ashio, and by modernizing and mechanizing equipment and facilities. In the 1880s and 1890s Ashio was by any international standard a top level mining operation 9) The decisions to make such investments were not, however, necessarily based on proper investigations or careful planning, but rather on Ichibei's insistence on "growth at all costs" 10).

While Ichibei showed a radical determination when it came to the "hardware" of new technology or the purchase of new mines, he was ultra-conservate in matters of managerial policy and structure. "Growth at all costs" was applied to the production department, but in management, and especially at the pivotal head office, he behaved like an old-fashioned merchant. The number of managerial staff employed at head office was totally inadequate to cope with the scale of the company's operations. In 1896, when, with 38.3% of the nation's total copper output, 28% of silver output, and 7.4% of gold output 11), the company was employing 20,000 workers, and was operating 17 mines including Ashio, and surveying a further 18, in addition to owning the Shinonome refinery, the Honjo refinery, and the Fukagawa coke factory, at head office there were only 14 staff, including Ichibei himself. The office, just 600 sq. yards in area, was part of the Furukawa residence, and most of the staff lived on the premises. The staff included one engineer, one accountant-cum-general affairs manager, one accountant, one wages manager, one sales manager, one purchasing manager, one transport manager, two general affairs managers, two clerks, and three office juniors 12) - hardly sufficient for an overall detailed grasp of the affairs of the company's wide-ranging operations. Head office's main tasks were limited to procuring finance and disbursing wages, sales, and the purchase of major items of equipment. It could do no more than issue general exhortations to the various company operations to increase production and was unable to give any concrete leadership in that direction. Production management was left entirely in the hands of the managers at each mine. Such a lack of coordination and control at the center meant that the mines were virtually independent and free to decide their own policies. In such circumstances, it was only natural that at Ashio, with its rich deposits of copper and its superior equipment, wage levels would be higher than at other Furukawa mines. Moreover, since company policy was to go all-out for greater market share, the introduction of piece rate systems to spur production was bound to lead to relatively higher wages for Ashio miners. Clearly then, one of the reasons behind the 'high wages' of Ashio mineworkers in the 1880s can be found in the very nature and objectives of the Furukawa Company management. It was now that Furukawa Junkichi stepped forward as the advocate of managerial reorganization and a policy of retrenchment rather than all-out growth. He was the second son of Mutsu Munemitsu and had since early childhood been Ichibei's intended adoptive heir. On account of his poor health, and also at Ichibei's insistence, he had spent a year as an auditing student of chemistry at Cornell University, but had otherwise received little regular schooling nor had he occupied any post of responsibility within the Furukawa organization until the age of 27. He had, however, taken the trouble to tour all the company's mines and had the opportunity to study Ichibei's methods at first hand at the head office in Setomonochô, and one can well imagine that he must often have listened to criticisms of and comments on Ichibei's headstrong, even reckless approach to management from his father, Mutsu Minemitsu and from the powerful financier Shibusawa Eiichi, who had dealings both with Mutsu and with Furukawa. It is not at all inconceivable that with the outbreak of the pollution disaster, Shibusawa set to work on Junkichi in order to rein in Ichibei's policy of "growth at all costs". Whatever may have been the circumstances, at the end of 1896 Junkichi persuaded Ichibei to let him reorganize the head office and assumed the leading executive position within the Furukawa family. His first move was to set up a 'general management department' with himself as head. Creating two new sections within the department, he appointed Kondô Rikusaburô as head of the new mining section, and Inoue Kôji as head of the new general affairs section 13). They were two of the few university graduates at head office; Kondô had graduated from the Imperial College of Engineering, and Inoue from Keio University. The mining section was to control and coordinate all the managerial aspects of the various Furukawa mines, while the general affairs section was to be responsible for all finances and accounts. Junkichi clearly intended to bring all aspects of production and finance under the direct control of head office. His next step was to separate Furukawa family affairs and company enterprises. Immediately after the issuing of the third pollution prevention order in June 1897, he opened a Furukawa Company Mines Office which was to oversee all company mining operations. The head office building at Setomonochô became the family residence, and temporary company offices were obtained at a new address: Yaesu 1-chôme 1-banchi. Ichibei was henceforth to be known by the new title of 'President' rather than the old-fashioned term motokata (master merchant). Junkichi then disbanded the new general management department and appointed Kimura Chôshichi and Okazaki Kunisuke to the new posts of managing director and director respectively 14). After the completion of the anti-pollution projects in December 1897, Junkichi embarked on a second set of management reforms. Four sections were created within the new Mines Office: a pits section, a commercial section, an accounts section, and a general management section. The commercial section and the accounts sections were further subdivided into three departments: sales, supply, and transport, and salaries, finance, and supplies, while the general management section had two departments: general affairs and secretarial. This structure constituted the new basic model of the Furukawa management organization 15). A memo circulated by Junkichi on the subject of the company reorganization clearly reveals his views of Ichibei's managerial regime. "In the midst of the complex developments in society today, when social obligations have to be fulfilled and necessary discipline exercised, a company like ours, which employs considerable numbers of people, and operates on a large scale will inevitably find it difficult to achieve success. The company's policy heretofore has placed emphasis on rapid expansion, and consequently, there has been no attention paid to any careful revision of regulations and principles or to day-to-day office management. The result has been an inevitable decline in employee discipline and office efficiency. It will therefore be necessary to take account of the fact that the company's pioneer expansionary phase has ended; in its stead ought to be instituted a policy of consolidation incorporating appropriate systems of control and executive order in accordance with which would be carried out the necessary revisions of company regulations" The main point of Junkichi's criticism was the "inevitable decline in employee discipline and office efficiency." The same points were lucidly made by Okazaki Kunisuke16) who was of great assistance to Junkichi in carrying out the restructuring: "Young Mr.Junkichi was of the opinion that old master Ichibei had been too liberal in his dealings and that if the pursestrings were not gripped tightly, money would be wasted no matter how much there might appear to be in the purse. In Mr. Junkichi's opinion, it was not right that 500,000 yen in profit, for example, should always immediately be translated into 500,000 yen in capital investment". Ichibei, of course, did not take this criticism of his methods lying down. Even in 1899, after the Mines Office was up and running, and it was no longer possible for him to exercise sole control, he was still insisting on the principles of "mining first" and "growth at all costs" 17). "From the time I first set my hand to the mining industry in 1874, I singlemindedly devoted myself to that industry, played an active part in it across the country and established various mining operations. I did nothing that was not in some way bound up with the industry. To the limit of my resources and my life, it was my intention to develop the industry to the fullest extent possible. Many people have expressed concern for my security and that of my family, and have kindly advised me to withdraw from such a dangerous occupation and engage in a more secure profession such as banking. The late Mutsu Munemitsu often advised me thus, even going so far as to send letters all the way from America expressing his cordial concern in this regard, but my conviction of over twenty years' standing only became firmer with time; I was determined not to let go my resolve to do whatever I could to develop the industry". Why then did Ichibei, the dictatorial creator of the firm and the archetypal owner-entrpreneur, convinced of the correctness of his own managerial principles, accept Junkichi's views and acquiesce in the establishment of the Mines Office and the restructuring of the company's management? The answer lies in the actions of Shibusawa Eiichi 18), who had long harbored serious misgivings about Ichibei's managerial policy. Taking advantage of Furukawa's need for loans to finance the anti-pollution construction projects, he withdrew his support from Ichibei, who had always had stuck to his rule of a "constant relationship with the Dai-ichi Bank", and turned instead to Junkichi. The circumstances are described in "The Life of Furukawa Junkichi": 19). "It was decided, as always, to apply to the Dai-Ichi Bank for a loan, but the bank's response was not encouraging; the reasons given were that it had already exceeded its own limits in extending loans to the Furukawa Company, and that in this case, the loan was for pollution prevention rather than for the purpose of increasing output. Ichibei was further asked to produce detailed proposals as to repayment. It was at this point that Mr. Junkichi stepped in and had a meeting with Shibusawa Eiichi. He thanked Mr.Shibusawa for the bank's assistance in the past, announced that from then on he was himself taking on reponsibility for the firm's financial affairs, and that if the business continued to progress as it was doing, the loan for the construction projects could certainly be repaid in regular six monthly installments; the precise details of repayment would be confirmed as soon as former debts had been cleared. At this one meeting, Mr. Junkichi was able to persuade Mr.Shibusawa and thus succeeded in securing the necessary loan". To avoid the compulsory closure of Ashio, the Furukawa Company's 'gold bucket', it was imperative for the company to complete the anti-pollution construction projects within the time stipulated by the government. All depended on the supply of the necessary funds. Ichibei was forced by pressures both within and outside the company to agree to a revision of the company's structure and managerial policy. How the changes affected AshioThe company reorganization was certainly not confined to head office. Every mine and factory was required to review its operations in line with the new 'policy of consolidation'. Ashio received the order to do so on the 10th August 1897 shortly after the opening of the Furukawa Company Mines Office and replied with a set of 'review proposals' on the 20th September. These constitute a significant document in that they describe various production problems during the 'mining first' managerial regime and also the basic changes that took place afterwards. We shall therefore quote it at length: 20): 1. In view of the present situation, monthly output is to be fixed at approximately 800,000 kin (480,000kg) per month.

The review proposals - the result of "serious consideration" - were incomplete, and consisted of various unrelated items listed in no particular order, a fact which in itself shows the level of office work at Furukawa enterprises during the long period when increasing productivity was the overriding concern. We shall therefore try to arrange the proposals more systematically and comment on each one briefly.

(1) The principal aim of the review was to cut operating costs (2,3). An average cut of 5.1% was indicated for each department of the mine. An increase of 23.1% was marked out for 'special construction works', but this was doubtless the extra expenditure needed to deal with the pollution problem. To cover the cost, "office expenditures" were slashed by 46.7%. What made the decision to reduce the scale of production possible was that the mechanizations and modernizations financed by continuous investment from the late 1880s until the 1890s had been completed with the connection in 1896 of Tsudô and the Yokomabu No. 1 shaft. As a result of this decision, work on the construction of the new electro-refining station at Nikkô was halted. It was partially resumed in 1903 with work on the Betsukura power station. The formal decision to complete the Nikkô station was taken the following year, and work began in 1905 21).

The new monthly output target was set at 480,000kg, or 5,760,000kg a year, slightly less than the 5,880,000kg a year which had been the norm since 1890. In fact, however, it soon rose to around 552,000-564,000kg a month (6,600,000kg a year). The revision of company accounting practices ([3] above) did not introduce budget systems; they had already been in use for some time. What was significant in this area was the new stipulation that "All operations are to be subject to strict budgetary control". The revision of bookkeeping practices was a key point of the changes, but since the question of changing from traditional accounts books to western-style accounts books had only recently been taken up at head office, it was bound to take some time for it to be fully implemented at all company offices. In connection with the accounts, great emphasis was put on better management of supplies and purchasing. Purchasing was cut back. "Rules are to implemented and strictly abided by in relation to the use of tools and equipment. Carelessness will be disciplined". This requires no explanation, but the following stipulation is less clear: "With effect from next month, each department office is to be responsible for its own office costs". Obviously, "each department office" means pits department, refinery department and so on, but whereas each department was now "to be responsible" for its own supplies and equipment, in fact, departments were not allowed to procure their own supplies and equipment; they had to be obtained via the supply department. The situation is explained in the following passage from a newspaper article which sought to account for the causes of the riot. 23) On arriving at Ashio and observing the various departments and offices at the mine, I was amazed to discover that each such department conducts its own business independently, and that even the smallest transaction between them has to be paid for. For example, ore-bearing rock extracted in the pits is sold to the ore dressing workshops where it is assessed for quantity and quality. The rock is then separated from the ore which goes to the refinery, which again has to pay for it and in turn sells the ore it refines to the relevant company department. The Supply Department sells food and other articles to the other departments, which then sell them to the workers at the bottom of the supply chain. Every six months, accounts are drawn up by each department, and profits are reported to the Mine Office. The company rewards departments which have made good profits by various bonuses and other emoluments, and promotes staff who have shown business acumen in the making of such profits. The result is fierce competition between departments, while the Nanking rice which is brought up the Ashio Pass along cableways is sold to the miners at a very high price." In other words, all departmental expenses which had formerly been included as such within the overall accounts for the Ashio mine as a whole were now separated out and had to be borne by each department. This was the reason, for example, why it was decided to cut the various costs incurred by the dressing department by as much as one half, and as a result, each department's cost-cutting target was not in fact 5.1%, but, due to the need to include the reductions of the dressing department, worked out at 8.4%.

By far the major element in the pits department budget was labor costs, which, for example, accounted for 85% of the department's budget of 155,943 yen for the latter half of 1888 24). Mechanization reduced this somewhat in the following years, but because there were no great advances in extraction methods (face workers accounted for half the underground labor costs), the overall reduction in pit department labor costs was small. The 8.4% cuts in departmental expenses were bound to have an effect on miners' wages. It is therefore hardly surprising that at a time when real wages nationwide were rising, at Ashio they were headed in the opposite direction.

[Notes]

1) "100 years of the Furukawa Company" p. 193. A = minus 2) Other enterprises included the Sachiu, Nagamatsu, Kune, and Fukugawa coke factory, and a number of coalminesfields in Kyûshû. The 'total' column includes figures from a number of smaller Furukawa operations not included in the 'others' column; it does not therefore tally exactly with the other columns in the table. 3) Ashio's profits in the early years of Furukawa ownership are thought to have been much greater than those shown here. For example, profits in 1885 were said to be 293,684 yen ("History of Tochigi Prefecture" p. 153). This is probably the amount remaining after dividends had been paid to Sôma and Shibusawa ("Documents from the Life of Shibusawa Eichi Vol. 15, p. 371). We shall turn finally to data which clearly reveal the results of the new managerial policy: the annual profits statistics relating to each of the main Furukawa enterprises and also to head office (see table 35). From 1886 Ashio showed a consistent annual profit of over 100,000 yen. In 1890, the final year of the Jardine Matheson contract, Ashio's profit was 150,000 yen, and the following year it soared to nearly 700,000 yen. During the 90s Ashio's profits fluctuated, and profits for the Furukawa enterprises as a whole were not so buoyant; they went into the red in 1893 and 1896. However, after the implementation of Junkichi's new strategy, the situation improved year by year. Overall corporate profits were 570,000 yen in 1898, 1,480,000 yen in 1899, 2,420,000 yen in 1900, and 2,500,000 yen in 1901. The improvement in the company's fortunes was considerably assisted by the fact that during this same period world copper prices began to rise again after being depressed during the late 80s and early 90s, but the achievement of steady annual profit levels of 1,500,000 to 2,500,000 yen after 1899 can certainly be attributed to the success of the new 'consolidation' policy. 3) Qualitative and Quantitative Changes in the Mining WorkforceHow did the changes affect Ashio miners' wage levels over the long term? In other words, why did the wages of Ashio miners, which had far exceeded those of any other group of workers in Japan in the early 1880s, decline in real terms from the late 1890s to the 1900s while nominally remaining static or showing a slight increase? Three question arise here. First, why were Ashio miners' wages so inordinately high in the early 1880s? Second, why did real wages decline from the late 1890s into the 1900s, and third, why were miners' nominal wages able to remain steady or increase slightly while those of refinery workers at Ashio declined in both real and nominal terms? Qualitative changes in the mining workforce

We have already examined the first two questions. The third question can be answered by investigating the qualitative and quantitative changes in the mining workforce during the period in question. There is no firm evidence as to whether explosives were in use when Furukawa took over at Ashio in 1877, but that they were definitely being used in the same year at another Furukawa copper mine, Kusakura, we know from a report in "The Bulletin of the Japanese Mining Industry Association" by Harada Shinji, a graduate of the Department of Metallurgy at Tokyo University's Faculty of Science, who visited Kusakura in 1885 25): "Since 1877 ore extraction methods had been based on those used at various state-owned mines. A number of improvements have been made since: makeshift bamboo pipe fuses were replaced by western-style fuses, while traditional Japanese iron drill hammers were replaced by western steel hammers. Since 1881 dynamite has been found to be very suitable for working with the type of rock at Kusakura, being three times more effective than gunpowder. Both are used these days, but dynamite is being used more frequently. They compare as follows: if the use of gunpowder and bamboo pipe fuses in the old narrow tunnels yields an amount of ore dug per man per day which could be considered as 1, gunpowder in the newer wider tunnels would yield a result of one and a half times. Dynamite yields a further increase of one and a half times" Since the two mines were owned by the same company, and technical staff and miners had been transferred to Ashio from Kusakura, it is hardly conceivable that western fuses and dynamite as well as explosives would not have been in use at Ashio from the very beginning. The first extant document confirming their use is from a letter of 1882 from Ichibei to Kimura Chôbei urging him to make greater use of dynamite. 26) An account of how they were actually being used at Ashio in 1885 is given in Ôhara Jun'nosuke's 'The Ashio Copper Mine' which we have frequently quoted 27): "When extracting ore, the rock beneath the lode is drilled first, and then, at suitable intervals branching shafts (90cm x 1m 50cm are drilled upwards. When a vein of ore is encountered, drilling proceeds to the right and left. Rock is broken up using octagonally-shaped steel drills and hammers to drill bore holes into which are placed explosive charges. When there are few naturally-occurring cracks in the rock, or when the rock itself is particularly hard or there is water present, dynamite is employed in place of gunpowder". This, of course, does not mean that explosives were first used at Ashio in 1885. It is known that they were being used before then, and in his 'Inspection Report on the Ashio Copper Mine, Tochigi Prefecture', Tashiro Naeomi states that 'for greater convenience following improvements made in 1885' 28), electric fuses were first used that year to ignite dynamite, which must therefore have been in use before 1884. Before the use of gunpowder, the miner's main job was to break up rock and extract ore. In tunneling new pits, tunnels, and shafts, the area to be tackled would be designated in blocks according to the hardness of the rock and was drilled following grains and cracks by either the vertical `kakeji or the horizontal butsudan method of drilling. The kakeji ('hanging scroll') method was used in following vertical grains or cracks; the upper area was drilled first, and the lower area was broken up from there. The butsudan ('Buddhist altar') method was used with rock that was more uniform and had few grains or cracks. The center area was drilled first, and drilling proceeded out to the right and left, then moved below the center, and finally, above it. Each designated area was assigned to one man; if there were few grains and the rock was very hard, the area would be greatly further subdivided; if grains were encountered and drilling became easier, the number of subdivisions was reduced. 29) The most important feature of the use of explosives both in pit-blasting and in extraction was the setting of the insert or bore hole. The type and size of the hole varied according to the hardness or softness of the rock and the number of fissures in it, but it was normally 30mm in diameter and from 30cm to 60cm deep. When new tunnels were blasted, several holes were drilled in a central position, the explosives inserted and then ignited. The same process was then repeated above, below, right and left of the original holes. Bamboo pipes filled with black gunpowder were first used as fuses, but as stated in the above-mentioned 'Report on Kusakura Copper Mine', western fuses were soon introduced. Electrically ignited fuses for dynamite blasting were used at Ashio from 1885. This allowed many simultaneous explosions to be made from a single ignition. Such fuses were also adapted for use with gunpowder. Extraction tools also changed. Traditional iron hammers and drills were replaced by steel gads (drills) and steel hammers which were known as 'settô' 30). The gads had splayed heads similar to the shape of the large plectra used for playing the shamisen (a traditional banjo-like stringed instrument) and shafts that were hexagonal in diameter. The gad was held in the left hand and hit with a 1.5kg settô held in the right hand. The gad was rotated with each strike, thus creating a circular hole in the rock. Water was poured into the hole from time to time to clear out fragments and dust, and a long steel pole called a kyûren was also inserted to remove larger pieces of rubble. As the boring went on, gads with smaller heads and longer shafts were employed. Where possible, the work was carried out by two men; the miner's mate would hold the gad which was struck by the miner wielding a 4.5kg hammer in both hands. Two-man drilling in this way was more efficient with less equipment wastage. Drilling such bore holes was not just heavy manual labor; it required considerable skill and experience. One had to be familiar with the rock, to know the different types of grain and crack, to judge the right angle and the right position for drilling, as well as the appropriate size and depth of the bore hole. After the bore hole was complete, it was filled to the bottom with blasting powder contained in wooden tubes and a fuse was inserted which was secured with a plug of dried clay. The fuse was then lit and the charge exploded. A succesful blasting depended on the amount of the charge, the way it had been inserted, and the order of firing, not to mention the appropriate use of gunpowder or dynamite for particular kinds of rock. Dynamite's greater explosive power could disintegrate even the hardest rock and it also had the advantage that it could be used for soft rock where there was a lot of water present. It was, however, more expensive than gunpowder and the choice of one or the other greatly affected the cost of the operation. Lack of skill in inserting gunpowder, and in connecting and igniting the fuses often led to blast failures, and sometimes, to fatalities. The use of explosives and the new steel tools did not, however, basically affect the nature of the dirty, strenuous, and dangerous job of the underground miner. The miner's traditional skills - being able to distinguish between types of rock, cracks and grains and of making efficient use of his tools in a cramped space - continued to serve him as well as they had done in the days before the introduction of explosives and dynamite. But his work was now considerably simplified, since it consisted mainly of drilling bore holes, whereas before, without explosives, all sorts of skills and tools had been required in the process of ore extraction. Putting up shoring posts was also traditionally part of the miner's work, but as Ashio expanded, this job was given to specialist 'shorers', thus reducing the number of skilled jobs a miner had to do. On the other hand, new knowledge, skills and technical abilities were called for in the handling of dangerous explosives and dynamite, locating the best places for explosions, and choosing the appropriate type of explosive. In this sense, the metalminer's job in the 1870s and 80s altered considerably, though not as drastically as the changes experienced by smelting workers. Change was not entirely absent from the ore extraction process; the shift from 'raccoon dog digging' to 'overhand stoping' at the end of the 1890s greatly affected the situation at the ore face (see chapter 2), though without actually altering the nature of ore extraction itself. The effects of the introduction of mechanical drillsThe miner's other main task - tunneling - was a different matter. With the introduction of mechanical rock drills, a completely new type of work was created which, at least in the case of the opening up of major tunnels, deprived manual miners of work. The first power rock drills at Ashio were of the Schramm type and were obtained in 1885 from the Ani mine which had recently been purchased from the government. They were first used at Ashio to drill the Ariki pit. 31) Naturally enough, they completely changed the nature of tunneling operations. They first required the installation of air compressors outside the pit, and these had to be connected to the drills at the workplace by steel pipes. The drills themselves, too heavy to be held without support, were mounted on special stands. The drill itself was operated by a single miner, but an assistant was needed to ensure the stability of the stand, to change the drill heads, and to move the drill's position. The drill heads also required cooling, and to make the work easier, water had frequently to be poured into the bore holes. Men were also needed to maintain and operate the power units and the air compressors, and to keep the drills in good working order, all of which added up to a sizeable labor force engaged just in drilling bore holes. The number engaged in this work at Ashio is unclear, but at Ani, where the same Schramm-type drills were used, a drilling team consisted of 13 operatives: one senior miner, one machinist, six miners, one haulier, two blacksmiths, and two carters. A team worked in 12 hour shifts, but each man's hours were much shorter, because setting up the drill took one hour, the actual drilling five hours, setting up and executing a blast two hours, and debris removal four hours. Carters' therefore actually worked only four of the 12 hours, while miners worked from six to eight hours. In a 12 hour shift, a team was able to tunnel an area 2.12 meters in height, and 1.81 meters in width, four times the average (50cm) possible with manual drilling. So far, I have employed the term 'miner' (kôfu), which was used at Ani, to describe the men who did this work, but in fact, the nature of their work was completely different from that of manual ore extractors and pit blasters. As we have seen, the manual miner's main job was the appropriate use of hammers and gads to drill bore holes. The efficiency of the job depended on his individual motivation, his judgment in assessing the type of rock, the right drilling angle, the size and depth of the bore holes, as well as his skill in placing explosive charges. By contrast, the main job of the power drill operatives at Ashio (where they were known as shinsakufu) was, as a team, to set up the cumbersome drill on its stand, drill the bore holes using drill bits of varying sizes, and then move the drill on after each hole was finished. Naturally, this job too called for some skill, knowledge, and experience, notably in deciding which drill bits to use according to the type of rock to be drilled. If the change to a smaller drill bit was not made at the right time, drilling would either make little progress or else the bit would get stuck in the hole. But it was no longer a case of efficiency depending on a single individual's skill and motivation; a whole team was now involved, and the work was also affected by the condition of various machines - the drill itself, the power engine and the air compressor. This is why wages for these workers were based on a fixed rate system rather than on a piece rate system as with manual miners. However, the situation in the pits department differed from that in the refinery in that these mechanical innovations did not immediately lead to the machine operatives - in this case, the shinsakufu - depriving manual workers of jobs. Even by October 1902 there were only 24 shinsakufu, a mere 1% of the total number of 2,737 miners and their apprentices 32). It was not until 1924 that the number of mechanically-equipped miners overtook that of manual miners 33). The reason why mechanization took so long can be attributed not only to the cost of investment in the necessary equipment, but also to the fact that, for management, it was simply more expensive to operate a mechanized mine than a manual mine 34). Also, due to the limits of technology at the time, power drills were both heavy and unwieldy. Moving them required considerable manhandling, and moreover, they could only be used effectively for drilling near the entrances of main tunnels 35). Despite these drawbacks, power drills were used because they obviously speeded up the pace of work. In their early days at Ashio in the early 1880s they were already twice or three times as fast as manual digging, and in the 1890s when workers had become accustomed to them, efficiency rates were even higher. They were able to cope with the hardest rock that often frustrated the efforts of manual miners, and could be used even in places where ventilation was bad due to their being powered by air pressure. The traditional problems of mining - poor ventilation, drainage, and underground transport - could only be overcome by cutting more tunnels, and obviously anything which enabled the job to be done in the shortest possible time would bring cost benefits in the long run. Quantitative changes in the mining workforceAs with wages, reliable data for quantitative changes in the mining workforce exist only for the 1880s and 1900s. However, since we know the amount of ore smelted each year and also the amount extracted except for a period of a few years, it is possible to make an educated guess at the numbers of miners (see table 36). The figures for the numbers of miners shown in the column on the far left are based on documented evidence and are therefore reliable. The basis of the conjectured figures in the column to the right must now be explained in some detail. compressors cost 2,460 yen and were manufactured by Akabane Engineering Workshops. Motive power at Ani was provided by water wheel and at Ashio by a 150 h.p. steam turbine. Running costs at Ani were 22 yen 50 sen per meter drilled; manual drilling cost 15 yen per meter (Mita Shuichi 'From the Tunnels of the Ani Mine' ("Bulletin of the Engineering Society" No. 47, Nov. 1885.)

[Notes]

1)No. of miners (1)1877 figs.: "100 Years of the Furukawa Company" p. 58. (2)1882: "The Life of Furukawa Ichibei" p. 20. (3)1883, 1885, 1894:The History of Tochigi Prefecture" pp.8, 25, 491, (4)1884: "Bulletin of the Engineering Society" Vol. 34, (5)1886: "The Japan Labor-Management Yearbook" (I) p. 209, (6)1896:"An Outline of the Ashio Copper Mine", (7)1900: Kamiyama Tatsuzô Observation Study Report p. 18, (8)1901:"The Ashio Copper Mine Illustrated", (9)1902: Hasunuma Sôun "The Ashio Copper Mine", (10)1905: "The History of Tochigi Prefecture" Letters and Documents 8, p. 621, (11)1906:"The Treatment of Miners". Other data relating to numbers of 'miners' does exist, but as it invariably includes figures for hauliers and other laborers, it has not been included here. 2)Ore extracted (1)1880, 1885, 1886: "The Life of Kimura Chôbei" pp. 51, 89, (2)1881, 1887: "The History of Tochigi Prefecture" pp. 147, 150, (3)1882-84: "The Life of Furukawa Junkichi" pp. 34, 40, (4)1894-96: Kibe Kazue Observation Study Report p. 8, (5)1899, 1900: Hosoya Genshirô Observation Study Report p. 256, (6)1901-1905: Ôkawara Saburô Observation Study Report, (7)1906: Furuichi Mutsumi Observation Study Report p. 12. 3)Ore smelted (1) Before 1896: Sakikawa Motarô Observation Study Report, (2)after 1897: "The History of Tochigi Prefecture" pp.124-125. 4) All ore figs in this table are in units of 10,000 kan (1 kan = 3.75kg) except those in the column "Ore smelted per miner" Figures for the amount of ore smelted were used as a basis for the estimate because of their consistency throughout the period in question. The figures that ought most properly to have been used are those for ore extracted, but unfortunately, such data for the years 1888-1893, 1897 and 1898 are missing. Certain problems arise when applying the figures for ore smelted in order to estimate the numbers of miners. Firstly, when the amount of ore extracted exceeded the capacity of the smelters to refine, it was carried over into the figures for the following year, so if the figures for ore smelted in the first year are used without adjustment, the estimated number of miners for that year will be too small and that for the following year too large. However, it is at least well-known that the years when this happened were 1884, 1887, and 1897. In 1884 there was a sudden glut of ore extracted; 1887 was the year of the Naoribashi refinery fire, and in 1897 the Pollution Prevention Order was issued; in each case a certain amount of ore smelted was carried over to the following year. The same might well have occurred in 1890, the last year of the contract with Jardine Matheson, when there would likely have been a boost in output. Records for the following year show a substantial increase in the amount of ore smelted compared with the previous year. It is likely that the 1891 figure includes the amount which the refiners were not able to cope with in 1890 and which was carried over. Also, 1891 was the year in which the refineries completed full conversion to semi-water jacket furnaces and were thus able to cope with more substantial amounts of ore. These points have to be taken into account in order to cut down the margin of error when making an estimate of the number of miners. The second problem concerns the variability of the extracted ore. In any one year the quality of the ore and the hardness of the surrounding rock was bound to change and thus affect each miner's total amount of ore smelted. Also, the number of miners allocated to extraction and the number allocated to tunneling also changed each year. But these problems would occur even if one had available the necessary data for extracted ore; all one can do is compare sets of data for years either side of those years in which the figures are unusually divergent.

A third problem is that, irrespective of the amount of ore extracted, increased efficiency in ore dressing would necessarily lead to more ore being smelted, and together with improvements in refining capacity, would enable lower grade ore to be refined. The effect of this would tend to raise each miner's total of refined ore. On the other hand, while refined ore totals compared well with extracted ore totals when ore dressing and smelting efficiency was low and extraction was by the 'raccoon dog' method, they dropped after the introduction of overhand stoping. These factors will also be considered in the following analysis of the amount of refined ore per miner.

The reasons for the increases are clear enough. While mechanization was proceeding apace in ore dressing, and western-style furnaces were being successfully introduced in the refineries, making possible continuous large-scale production, technological developments in the pits were mainly of an indirect nature affecting transport, drainage, and ventilation; after the 1890s there were no direct innovations in the extraction process itself. However, certain factors peculiar to Ashio must be noted here. The ore dug in 1884 and 1885 came from a soft clay-like rock which was easy to work; the seams were broad and the ore was of the highest quality. These favorable conditions lasted but a short period. On his inspection visit to Ashio in 1885, Harada Shinji noted that "while the best ore in the Yokomabu lode was, at its peak, found in veins 2.42 meters wide and 90.9cm long, it is currently on average 90.90cm wide and from 21 to 24cm long"35). The Yokomabu had thus already peaked by late 1885. Average output (ore extracted) per miner in 1884 had been 16,950kg, but this fell to 15,071kg in 1885 and 12,367kg in 1886. By 1896 the average refined ore total per miner was as low as 9,937kg. This low figure in 1896 was not due to any fall-off in miners' efficiency; the output per miner of class one ore was, at 19,447kg, well in excess of figures for 1884 and 1885 - 16,950kg and 15,071kg. Rather, the figures for those two years must be regarded as exceptional, having been boosted by finds of unusually rich veins of ore. Another reason for the very small increase in the amount of ore refined per miner from the 1880s to the 1900s can be traced to the effect of the introduction of overhand stoping in the late 1890s. The new method, which meant digging an entire designated area of rock instead of only the parts containing rich deposits of ore as had been the case with the raccoon dog method, was bound to lead to a drop in the amount of ore refined relative to the amount extracted. The figures for 1896 show this plainly. The figures corresponding to amounts of ore dug per man in 1894, 1901, and 1902 exceed the figures for the 1880s. We shall now consider the question of the amount of ore refined per miner, which we have selected as the basis for our estimate of the number of miners. Turning first to the period from the late 1880s to the early 1890s and leaving out the exceptional years of 1884 and 1885, the years to consider are 1886, 1894, and 1896. During these three years the average amount of ore refined per miner was 11,400kg, an amount not very different from that estimated for 1887-1895 (11,625kg). However, it was indicated earlier that part of the total for 1890 was very likely carried over to the following year; the estimate for 1890 is thus 26,250,000kg and that for 1891, 25,166,250kg. In May 1897 the 3rd Pollution Prevention Order was issued, the Kodaki refinery closed, and refining was continued at the Honzan refinery along with the construction of desulphurization chimneys. Since the construction work had to be completed by a certain date, miners from the pits were brought in to help with the work. The estimated figure for ore refined per miner in 1897 is therefore 9,375. To provide the basis for an estimate of the number of miners after 1898, since the average amount of ore refined per miner during the five years after 1900 when miner numbers are known was 18,401kg, we have adopted the figure of 15,375kg. Although the estimates of miner numbers are, of course, only to be regarded as guides, the margin of error is probably quite small. Seasonal fluctuations in the Ashio labor force were still marked, so that a cross-section of the workforce at any one time was not necessarily representative of the average size of the workforce as a whole. In 1901, for example, there were 3,373 miners in December as against 2,719 in June 36). Calculating the number of miners from refined ore totals gives a figure of 3,092 for the year. It is surely appropriate to consider the figures for other years as being similarly affected by seasonal fluctuations. 4) Characteristics of Long-Term Changes in Wage LevelsA horizontal mobile labor marketNow that the qualitative and quantitative changes in the Ashio mining workforce have been clarified, it becomes possible to analyze long-term changes in wage levels. In the 1880s Ashio wages in all job types were far superior to those in other industries and mines, but this was particularly the case with skilled workers such as miners and refinery workers. Skill acquisition in these jobs took time, and whenever greater numbers were needed to meet a sudden demand the only way to secure the necessary workers was to headhunt them from other mines, which meant paying substantial wages to men who were already relatively well-paid nationwide due to their limited numbers in absolute terms. The ore being dug at Ashio at that time was of high quality from soft rock, and the work was not far from the pitheads. In addition to the high wages, these were attractive working conditions for any miner, who could be sure of making a sizeable profit for himself.

And yet, refinery workers' wage levels fell sharply during the 1880s, both in real and nominal terms. Miners' wages also fell in real terms, but their nominal wages continued to show modest increases.

There were no such decisive qualitative changes in the mining workforce until the late 1900s. Power drills were still technologically at a primitive stage; they could only be used for opening up new tunnels and were far more costly than manual extraction. Mechanization of that process was simply not yet feasible.

[Notes]

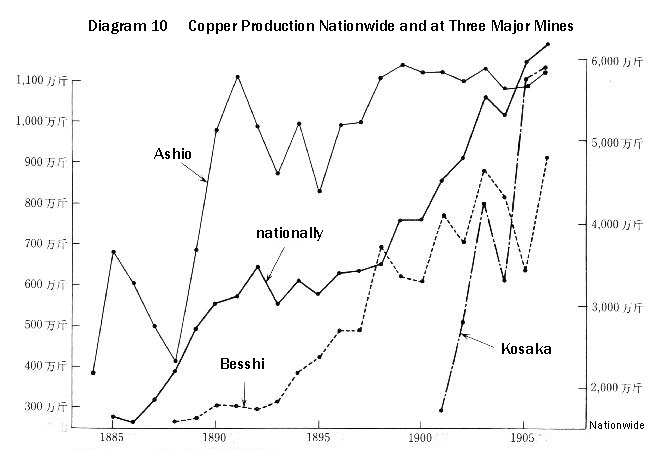

1) Compiled from statistics in "An Industrial History of the Meiji Period" Mining. 2) production figures in this table are in units of 10,000 kin ( = 6 ton)

The problem to be solved therefore is not so much why Ashio miners' real wages fell in the 1890s and the early 1900s, but rather, why did their nominal wages continue to rise during that depressed period?

[Notes]

1) June 1906 2)Ôkawara Saburô Observation Study Report p. 85 What stands out is the number of refinery workers, especially smelters, who have been doing the same job for many years. By contrast, miners were the largest single occupation group in the metalmining industry and their skills were readily applicable at any mine. Another factor facilitating miners' mobility was the custom of 'watariaruki' (changing mines, lit. 'tramping') which was supported by the miners' own fraternal organizations, the tomokodômei. Table 38 shows mineworkers in the Ashio pits department in 1909 by occupation and length of service.

[Notes]

1) June 1909 2) Furuichi Mutsumi Observation Study Report p. 62 Even leaving out those who would naturally not be included in any long-service category, such as apprentices, the proportion of long service employees is certainly low; 65.8% of all miners had only been working at Ashio for three years. A mere 1.5% had been at Ashio for more than 15 years. By contrast 17.2% of refinery workers had been employed for more than 15 years; the figure for smelters alone is 31.9%. Further evidence of the mobility of Ashio miners is the fact that at the end of 1901, 3,373 miners were registered employed at Ashio, but during the same year 3,278 miners quit, and 3,533 were taken on 37). In other words, there was turnover of the entire mining workforce. There were, of course, some miners at Ashio - though only a few - who were averse to moving on and were old hands, but the more mobile miners must have been quitting and finding work elsewhere at least once a year on average. These men were above all out to earn a higher nominal wage, and managers who wished to cut wages had to be prepared to lose miners. Another major factor contributing to mobility in the labor market was that metalminers could always find work in coalmines. Apart from a few years such as 1897 and 1906, demand for labor in metalmines nationwide continued fairly restrained, but in coalmining, it maintained a steady increase until 1920 38). Since it was similar work, also underground, coalmining drew away many metalminers. In the 1890s and 1900s especially, the key miners in the coal mines of Hokkaidô and Jôban were all ex-metalminers, notably from mines north of Tôkyô. Furthermore, the coalminers' wages were generally better than those of metalminers; the wages of the coalminers of Hokkaidô were especially high. For example, while a miner at Ashio in 1906 earned an average 72 sen 5 rin, his counterpart at Yûbari was drawing an average 1 yen 34 sen 3 rin. The danger of gas explosions in coalmines and the severity of the Hokkaidô winters make a simple comparison with Ashio nominal wages invalid. But the fact that it was nevertheless possible for miners to feel drawn to a job where they could earn nearly twice their current wage certainly made managements think twice before cutting miners' wages. Just before the riot, Minami Sukematsu, seeking to encourage men to join Shiseikai, pointed out that (Ashio) "wages are low compared to those in Hokkaidô" 39), and, "he greatly raised the men's spirits by declaring that if they were laid off because of union activity he would lead thousands of them, if need be, off to Hokkaidô" 40). The third factor is of less significance than the second, but worth mentioning nonetheless. In the late 1890s, Besshi, and in the 1900s, Kosaka, were growing rapidly. Output at Besshi had remained at levels of between 1,200,000 and 1,800,000kg until 1893, but it then rose sharply, challenging that of Ashio: 1894 - 2,352,000kg, 1896 - 2,940,000kg, 1898 -4,170,000kg, 1901 - 4,638,000, 1903 - 5,346,000kg. Kosaka succeeded in perfecting its own self-smelting refinery, and from 990,000kg that year, output rose to 3,048,000kg in 1902, and drew level with Ashio at 6,600,000kg in 1905. This rapid growth at both mines was accompanied by a substantial increase in the size of the workforce. Management at both mines sought to secure their labor by offering 'high' wages, which is why in 1906 the average wage for a miner at Kosaka was 1 yen 1 sen 7 rin, and at Besshi, 83 sen 8 rin - both higher than the average at Ashio. Notes

1) Shigeno Kichinosuke ed. "The Autobiography of Kimura Chôshichi" pp. 168, 255-256. 2) Itsukakai "The Life of Furukawa Ichibei" p. 132. 3) Furukawa Company Ashio Copper Mine "Outline of Anti-Pollution Measures Taken at Ashio Copper Mine" pp. 4-8 4) "Outline of Anti-Pollution Measures", pp. 28-29. 5) Furukawa Company Ashio Mine pub. "An Outline of Anti-Pollution Measures Taken at Ashio Copper Mine" p. 32. 6) Following his failure in the cotton trade, Ichibei "pulled out of the cotton business in 1877, turned to mining, and adopted the company trademark of "A", 'mining first' ("The Life of Furukawa Ichibei" p. 92). For 'growth at all costs', see pp. 2-3 of the same volume. 7) "100 Years of the Furukawa Company" pp. 78-81. 8) Ichibei's righthand man at head office, Inoue Kôji, described his boss' character in the following words: "He was always energetic and optimistic and never seemed worried about anything. When he felt that something was right, he made sure that it turned out just as he intended; he was a man of real conviction". (Itsukakai ed."The Life of Furukawa Ichibei" addendum p. 45). Ichibei's desk mottos were "fortune, blunt and perseverance". 9) For example, electricity was introduced at Ashio in 1890, a year before its use at Calmet & Hecla which, with 40% of Michigan copper, was the world leader. Ashio also began using electricity for drainage pumps and winding gear some 10 years before C &H, while electric powered trucks were first used at Ashio in 1897 and at C & himself. The office, just 600 sq. yards in area, was part of the Furukawa residence, and most of the staff lived on the premises. The staff included one engineer, one accountant-cum-general affairs manager, one accountant, one wages manager, one sales manager, one purchasing manager, one transport manager, two general affairs managers, two clerks, and three office juniors12) - hardly sufficient for an overall detailed grasp of the affairs of the company's wide-ranging operations. Head office's main tasks were limited to procuring finance and disbursing wages, sales, and the purchase of major items of equipment. It could do H in 1904. Total motive power for all engines and machinery at Ashio in 1892 amounted to 1600 h.p. For C&H, see William B.Gates Jnr., Michigan Copper and Boston Dollars, Harvard University Press, 1951, pp. 66-69. 10) An example of this is his investment in Matô power station in 1890. Hermann Kessler of Siemens, which had supplied the generators for Japan's first hydroelectric power station, later wrote: "I myself drew up the written estimate in the presence of (Furukawa Company) executives. Several hours later it was conveyed to Mr. Furukawa, but after asking only a few simple questions, he straightaway placed an order" ("The Life of Furukawa Ichibei" p. 199). 13) Itsukakai ed. "The Life of Furukawa Junkichi" pp. 97-99. 14) "The Life of Furukawa Junkichi", pp.104-106. 15) "The Life of Furukawa Junkichi", pp.107-109. The main points of the '2nd Management Review' are given in "The Life of Furukawa Junkichi" as follows (all references are to executives): "1. Each executive's bounds of authority and responsibilities are to be clearly delineated. 16) Susukida Sadataka ed. "The Life of Konda Bunjirô" (Kôkonkai, 1929) p. 548. 17) Itsukakai ed. "Conversations with the Boss" pp. 84-85. 18) Shibusawa's misgivings about Ichibei's management policy were indeed serious. He even went so far as to allow them to be recorded in "The Life of Furukawa Ichibei": (Ichibei) "tended to be too obsessed with his work. No doubt, he certainly liked his work, and this was what led him to buy up one mine after another in a carefree, even careless, fashion. He would simply give a mine a casual inspection and then immediately proceed to purchase. He did occasionally have more detailed inspections carried out, but for the most part, bought on impulse - hardly a recommendable business practice. We were most concerned about this, and at one time warned him to desist from such purchases. Since we were not reassured by a verbal commitment, we even required him to sign a written understanding that he would refrain from further expansion of the business. But his habit was not so easily checked, and he failed to heed the advice of his seniors and friends." ("The Life of Furukawa Ichibei" appendices pp.10-11). 19) Itsukakai "The Life of Furukawa Junkichi" pp. 118-119 20) "The Japan Labor-Management Yearbook" (I) Supplement 2 p. 87, 21) Itsukakai "The Life of Furukawa Junkichi" pp. 215-218. 22) "The Life of Furukawa Junkichi", p. 93. 25) 'Report on the Kusakura Copper Mine' ("The Bulletin of the Japanese Mining Industry Association" No. 15, May 1886, "Collected Documents of the History of Mining in Japan No. 1 The Meiji Period (4) "The Ashio Copper Mine" p. 56). 26) Shigeno Kichinosuke "The Life of Kimura Chôbei" p. 55. 27) Labor History Research Group ed. "Historical Documents of the Japanese Labor Movement" Vol. 1, p. 79. Although it was the norm to use explosives, they were avoided in cases whenever rock was found to contain much clay. Harada Shinji, who wrote an inspection report on the Kusakura mine, visited Ashio at this time, and later noted that: "Hard ore veins have to be tackled with hammers and and hand drills, and rock is blasted with gunpowder. When gunpowder cannot be used owing to the presence of extremely hard rock or water, recourse is had to dynamite". ("The History of Tochigi Prefecture" p. 22). 28) 'Inspection Report on the Ashio Copper Mine, Tochigi Prefecture' ("The History of Tochigi Prefecture", p. 20). 29) For a detailed discussion of the historical development of methods of extraction, see articles by Murakami Yasumasa: "Mining Papers [II]" (1986), 'Manual Mining Methods in the Early Modern Period' ("Studies in Japanese Mining History" Vol. 10, March 1982, 'Mining Methods at Ashio Copper Mine' ("Technology and Culture" Vol. 3 No. 2). 30) For the first use of power drills in Japan, see Mita Shuichi 'From the Tunnels of the Ani Mine' ("Bulletin of the Engineering Society" No. 47, Nov. 1885. 31) Hasunuma Sôun "Ashio Copper Mine" (Kôdô Shoin, 1903) p. 80. 32) Ichihara Hiroshi 'Labor Relations in the Copper Industry after the First World War'("Historical Studies" No. 522, Nov. 1983) p. 8. 33) The price first paid at Ani for a set of two Schramm-type power drills was 800 yen. Air 34) For the use of power drills at Ashio in later years, see Murakami Yasumasa "Mining Papers" [I][II] (1986) 35) Harada Shinji 'Report from Ashio Copper Mine' ("Collected Historical Documents of the History of the Japanese Mining Industry" Vol. 1 The Meiji Period ("The Ashio Copper Mine" p. 25). 36) "The History of Tochigi Prefecture" Letters and Documents 8 Modern 3, p.622. 38) Nimura 'The Number of Mineworkers in the Early Period of Japanese Industrialization' table 7 ("Monthly Research Bulletin" No. 289). 39) 'Second Deposition by defendant Minami Sukematsu' ("The History of Tochigi Prefecture" Historical Documents - Modern 2, p. 602). 40) 'Judicial Decision in the Ashio Riot Case' ("Historical Documents of the Japanese Labor Movement" Vol. 2, p. 228.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||